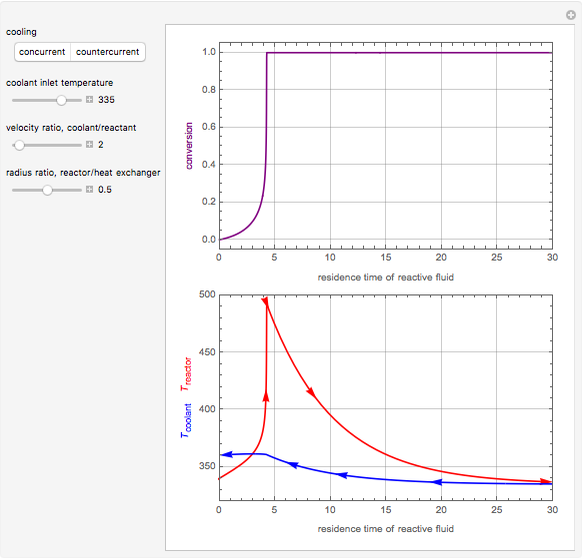

Concurrent and Countercurrent Cooling in Tubular Reactors with Exothermic Chemical Reactions

Description

The objective of this simulation is to observe thermal runaway in a tubular reactor and identify the critical parameters that represent the crossover from a thermally well-behaved reactor to one that exhibits thermal runaway. Consider a chemical reactant that is converted irreversibly and exothermically to products in a tubular catalytic reactor. The reactive mixture in the inner pipe flows from left to right and is cooled using a concentric double-pipe heat exchanger. The cooling fluid in the annular region can flow either concurrently or countercurrently with respect to the reactive fluid.

This simulation runs on desktop using the free Wolfram Player. Download the Wolfram Player here.

About

Author: Clay Gruesbeck. Open content licensed under CC BY-NC-SA.

View the source code for this simulation